MANUFACTURE SOLUTION CONSULTING

Are you looking to elevate your manufacturing operations in the U.S. but unsure where to begin?

Interested in optimizing your production efficiency and reducing operational costs?

Have you faced challenges in adopting new technologies or streamlining processes?

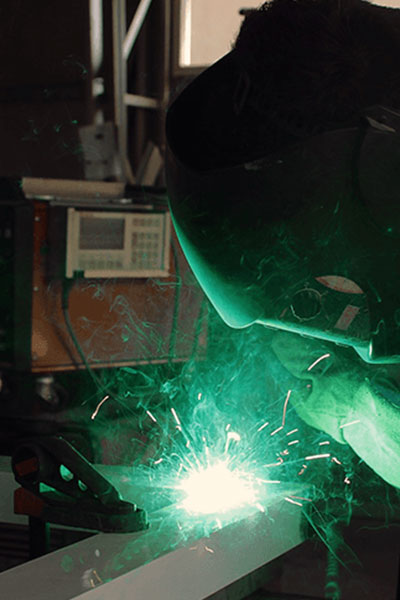

Partner with Manufacture Solution Consulting to guide you through every step, ensuring innovation, quality, and growth for your business.